Metalworking

Polishing

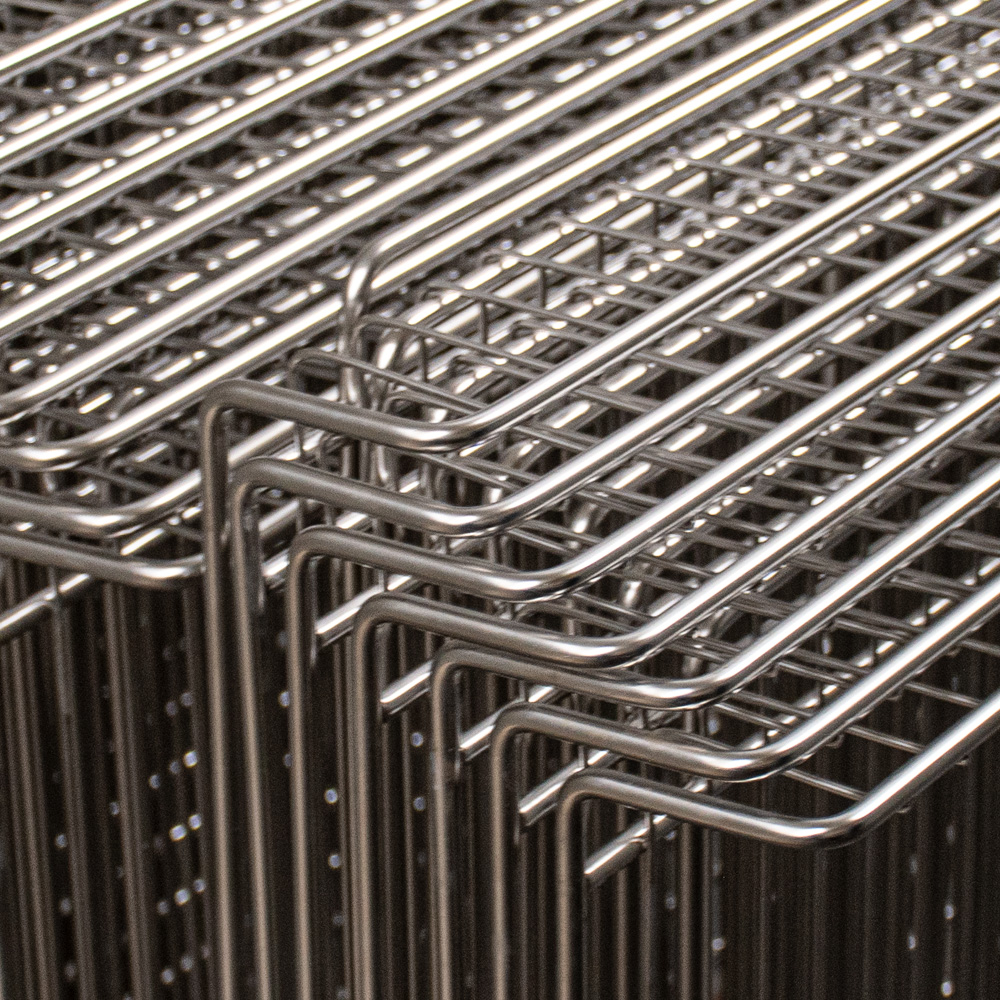

The entire polishing process is divided through a series of carefully designed steps, involving the application of specific chemicals and the use of specialized instrumentation. Initially, the surface of the stainless steel is carefully prepared through the removal of any impurities, oxides or residues from previous processing. This preliminary step is essential to ensure a flawless end result.

Brightening is not only an aesthetic process, but also assumes a crucial role from a functional point of view, helping to prolong the life and performance of metal components. The applications of stainless steel brightening range from manufacturing industries to the production of design objects, imparting a flawless finish to items ranging from furnishings to complex machinery parts.

This chemical process is capable of transforming not only the aesthetic appearance, but also the performance and durability of stainless steel artifacts, helping to meet the high quality standards required in a variety of industries.